Provided Services

Semiconductor heat spreader processing service

Scope of application:

DG Solutions is a Integrated heat sink and substrate processing for high-power semiconductors (T/R transistors, IGBTs and other wide bandgap semiconductors).

Applicable materials:

Diamond copper, diamond aluminum and other diamond metal composites, aluminum-based silicon carbide, molybdenum copper and other advanced heatsink and substrate materials.

Tech Advantages:

Heat sink and substrate integration can reduce one solder layer with low thermal conductivity, the risk of pseudo soldering, and multiple packaging steps. And it can enhance the thermal conductivity of the semiconductor, combining with materials (Cu-Diamond), the junction temperature is much higher, and a significant performance can be gained.

- For hard and brittle materials: Non-contact precise machining to ensure the mass production capacity, yield rate and dimensional accuracy of the material.

- Cold polishing: Almost 0 degradation effect, and the material denaturation layer is less than one-tenth of the traditional processing method.

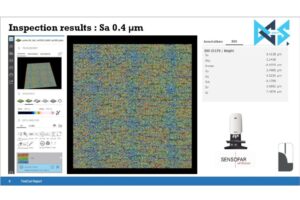

- Surface roughness: Ra 1.6 – 0.4 microns, up to Ra 0.1 microns, thinning coating and increasing bonding force.

- No tool marks on the surface, no impurity residue: No tool marks under 100x inspection. No grinding, sandblasting and other processes involved, simplifying the overall process and ensuring the quality of the coating.

- High yield: Fully automatic unmanned production line, full process inspection, high consistency and reliability.

High Precision Processing Gallery

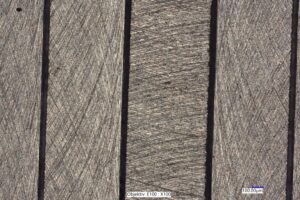

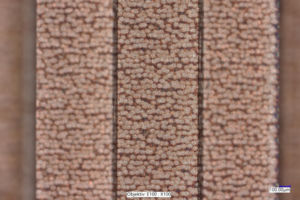

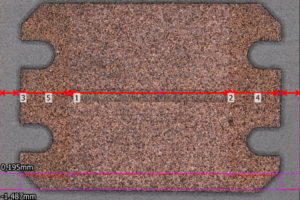

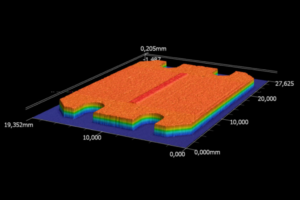

Molybdenum Copper

- Before polishing

- After polishing

- Batch

- Detail

- Inspection results

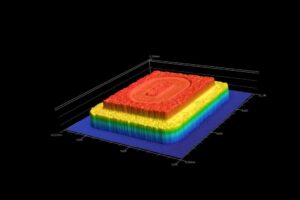

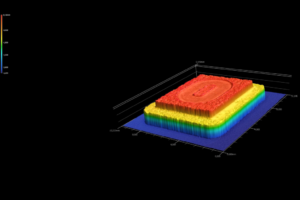

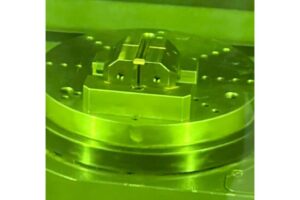

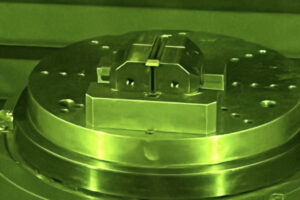

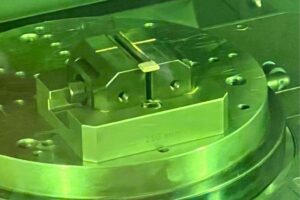

Diamond Copper

- Diamond copper

- Diamond copper

- Diamond copper

- Diamond copper

- Diamond copper

- Process

- Process

- Process

Surface processing of high-end transparent materials

Scope of application:

Surface processing of high-end transparent materials .

Applicable materials:

Single crystal quartz glasses, diamond, Silicon carbide, High transmittance glasses

Tech Advantages:

Surface processing is a crucial step in the fabrication of high-end transparent material parts like single crystal quartz glasses, diamond, silicon carbide, and high transmittance glasses. These materials are often used in demanding applications such as dihedral corner reflector array, optical lenses, mirrors, and windows, where their high transparency and mechanical properties are essential.

Single crystal quartz glass, diamond, silicon carbide, and high transmittance glass all require surface processing to achieve the desired surface finish and optical properties. In addition to lapping and polishing, our technology can be used for surface processing of high-end transparent materials. This can be used to modify the surface properties of the material, such as its roughness(Ra 0.01), hardness, or adhesion, without causing damage to the bulk material.